Spandrel Panels Cladding Things To Know Before You Buy

Table of Contents3 Simple Techniques For Spandrel Glass ColoursSpandrel Glass Backpan Fundamentals ExplainedNot known Facts About Spandrel Panels Cladding

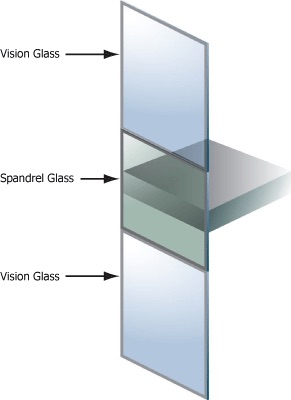

The infill wall is the sustained wall surface that closes the perimeter of a structure built with a three-dimensional framework structure (normally constructed from steel or strengthened concrete). The structural structure ensures the bearing function, whereas the infill wall surface offers to separate internal and also external area, filling up the boxes of the outer frames (how much does spandrel glass cost).

The infill wall surface is an exterior vertical opaque sort of closure. Relative to various other classifications of wall, the infill wall surface varies from the partition that offers to divide two indoor areas, yet also non-load bearing, as well as from the tons bearing wall surface. The latter executes the very same features of the infill wall, hygro-thermically as well as acoustically, yet executes static features also.

The safety versus fire is one of the requirements that is often required to enclosures walls - how much does spandrel glass cost. As normally the a lot more typically utilized products (blocks, bricks as well as mortar) are not fuel items, it is reasonably very easy to achieve the demands connecting to the restriction of spread of fire, thermal insulation and also structural strength, which in extreme instances, have to be assured for 180 minutes.

The Of What Is A Spandrel Glass Panel

This requirement has a direct impact on the building of the wall surfaces. The thermal guidelines are requiring progressively greater worths of thermal resistance to the wall surfaces. To fulfill these needs new products as well as building systems, which guarantee that the thermal resistances asked for by the laws will be offered, are created.

Local behavior [modify] The primary problems in the regional communication between framework and also infill are the development of short beam of light, short column impact in the architectural aspects. The areas in which supplementary shear forces can take place, acting in your area on the extremities of the light beams as well as columns, need to be dimensioned and transversally strengthened in order to surpass safely these forces.

Spandrel Glass Curtain Wall Things To Know Before You Get This

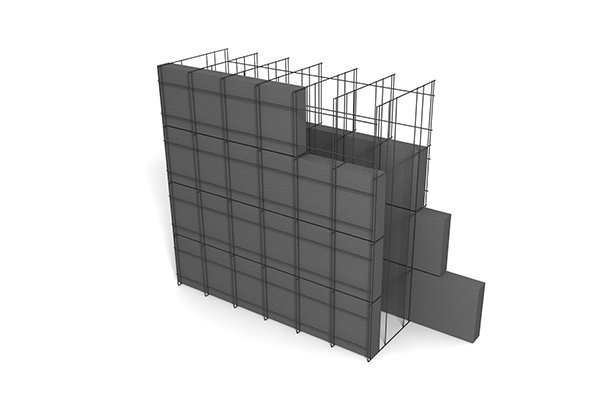

[modify] Intro are a form of cladding developed between the architectural participants of a building. The architectural framework offers assistance for the cladding system, as well as the cladding offers splitting up of the internal and also outside environments. Infill walling is different to various other kinds of cladding panel in that it is repaired between framing members instead than being affixed to the beyond the structure. Various other practical requirements for include: [modify] Kinds of Traditionally, utilized brick/masonry or timber; nonetheless, these are even more time consuming than modern alternatives and have actually been greatly replaced by lightweight steel C-areas that period in between floorings and around openings. These can be constructed from clay blocks or concrete blocks, in a strong or cavity type. They can be linked to columns utilizing wall surface ties cast at 300 mm centres, or located in anchor ports. It has diamond-shaped openings over its surface area, giving it an unique look. These panels supply premium toughness for a structure facade or other application. For structural stability and an addition to the style of your building, stairway, walkway or other location, pick these infills.

Holes in the form you need are punched right into steel sheets to offer a strong product that stays resilient. You can obtain round, square, slotted and various other holes in numerous various patterns that work for the layout you want. Infill panels are used between posts of guard barrier to create the obstacle for fall protection on staircases, terraces, and also pathways. Perforated infill panels, woven wire panels, or laser cut panels use interesting means to fill up the room in between posts. Infill panels are frequently installed on structure exteriors as a curtain wall surface, a rainscreen, or support for other cladding material. Steel infill panels offer a wonderful method to add safety to locations that need that. They are reasonably light weight and also can be added or removed as wanted. They let light and also air via and also can be developed with creativity to enhance the area as well as the appearance of the building. They permit airflow as well as supplies security from within, all while evaluating the view from the exterior and also offering a special and also interesting style for the building. There are numerous ways to cover a ceiling to hide the joists or trusses as well as energies that run in ceilings. One way is with using steel infill panels, especially when a much more commercial appearance is desired. Infill panels are a fantastic means to complete the areas of the assistance structure for canopies and sunshades. They supply shade, design, and also permanency. Bus sanctuaries, Park and Trip waiting areas, Band coverings, Parks, Zoos, Playgrounds, Residential real estate are all locations where infill panels are utilized. Aluminium shielded infill panels are built with a shielding core sandwiched between 2 slim aluminium sheets. Infill panels normally made use of for home windows, doors and curtain wall surface applications, supply high performance insulation for the building and also offer an appealing modern-day look. Getting involved infills create a composite structural system with the bounding frame, boosting the toughness and also rigidity of the wall system as well as its resistance to earthquake as well as wind loads. Non-participating infills are detailed with official site architectural spaces in between the infill and also the boundingframe to avoid the unexpected transfer of in-plane tons from the framework into the infill. Building of concrete masonry infilled frames is reasonably straightforward. The bounding frame is built of either strengthened concrete or structural steel, after that the masonry infill is constructed in the portal room. This building and construction series allows the roof or flooring to be built prior to the stonework being laid, permitting rapid building of subsequent tales or application of roof covering material. The system acts as a monolithic cantilever wall surface where small stress and anxiety focus happen at the 4 edges, while the center of the panel develops an about pure shear anxiety state. As packing proceeds, separation occurs at the user interface of the masonry and also the frame participants at the off-diagonal edges. Taking part masonry infills stand up to out-of-plane tons by a curving mechanism. As out-of-plane tons boost past the elastic read limit, flexural fracturing occurs in the masonry panel. This splitting(comparable to that which occurs in enhanced masonry )permits for curving action to withstand the used lots, offered the infill is built limited to the bounding frame as well as the infill is not also slender. If a space exists in between the infill and also the framework, the infill is considered getting involved if the gap is less than in.(9. 5 mm) and the determined variations, according to MSJC Code Area B3. 1.2. 1. However, the infill can still be created as a getting involved infill, provided the calculated strength as well as tightness are decreased by fifty percent

. The maximum thickness enabled is one-eighth of the infill height. The MSJC Code requires participating infills to fully infill the bounding frame and have no openingspartial infills or infills with openings may not be thought about as part of the lateral force standing up to system due to the fact that frameworks with partial infills have actually generally not carried out well during seismic events. The in-plane design is based on a braced frame design, with the stonework infill acting as a comparable strut. The width of the strut is determined from Equation 1(see Number 1). The term strut, created by Stafford Smith and also Carter(ref. 2 )in the late 60s, is the characteristic rigidity criterion for the infill as well as supplies a step of the family member stiffness of the frame and also the

infill. The angled strut is established within the panel as a result of angled tensile fracturing. Flexural splitting failure is uncommon due to the fact that splitting up at the masonry-frame user interface generally takes place first; then, the side force is stood up to by the angled strut. As gone over above, the small shear ability is determined as the least of: the capability infill corner squashing; the horizontal component of the pressure in the equivalent strut at a racking displacement of 1 in. 2.4, calculated along a bed joint. The variation restriction was found to be a far better forecaster of infill performance than a drift limitation. Typically, the infill toughness is reached at lower variations for stiff bounding columns, while more adaptable columns result in the toughness being managed at the 1-in.(25-mm)displacement restriction. 2 is for unreinforced masonry, use of equations from that section does not necessarily suggest that the infill material have to be unreinforced. The equations utilized in MSJC Code Section 3. 2 are much more clearly relevant to failing along a bed joint as well as are for that reason a lot more proper than equations from MSJC Code Section 3. The formulas made use of in the code are the result of contrasting various logical methods to speculativeresults. They are stamina based. The speculative results utilized for comparison were a combination of steel as well as strengthened concrete bounding frameworks with clay as well as concrete stonework. While some approaches offered by different researchers are rather intricate, the code formulas are fairly straightforward. As out-of-plane forces are put on the surface area of the

infill, a two-way arc develops, supplied that the infill is created limited to the bounding structure. The code equation designs this two-way arching action. As previously pointed out, the optimum density enabled computation for the out-of-plane capability is one-eighth of the infill elevation. Bounding structure participants that have various cross sectional residential or commercial properties are represented by balancing their properties for use in

the code formulas. NON-PARTICIPATING Continued INFILLS Because non-participating infills support only out-of-plane loads, they need to be described to avoid in-plane load transfer right into the infill. Therefore, MSJC Code Section B. 2. Connectors are not permitted to send in-plane tons. The stonework infill might be designed to span vertically, flat, or both.